Concrete pumps are tools used to convey liquid concrete from the source of concrete to the place of casting. Sories and the.

32 Meter 5 Section Zz Concrete Boom Pump Alliance Concrete Pumps

EN 12001 deals specifically with concrete pumps and is available from the National Standards.

. This guide discusses the use of pumps for transporting and placing. Concrete Pedestal Size 3 5 times pump motor mass Set 6 away from pump baseplate edge all sides Bush hammer floor slab Install Reinforcing steel into floor slab Apply bonding agent Pump anchors system. The Concrete Mix Design Manual for Nigeria like any document of this nature must be subjected to periodic review.

This is descri b e d later in the section on mix design. Ciently used in a concrete mix. This guide discusses concrete placement using the pumping method and how it affects the supplied concrete mixture when considering pumpability in mixture design and with the goal to obtain optimum concrete pumping results.

A concrete wall MATERIALS CONCRETE MIXER CONCRETE PUMP ROBOT CONTROL CONCRETE EXTRUSION REINORCEMENT DESIGN Robot-based 3D Printing Process. For example easier and quicker replacement of wear parts. Although concrete pumping has been used to place concrete since the 1960s there is still a lack of exact knowledge supported by research evidence as to what affects concrete.

Safety is a major concern of every person involved in the concrete pumping industry. For given proportions of cement and aggregates without admixtures the higher the slump the wetter the mix. Available in TerraPro concrete pump applications to maximize performance and fuel economy while reducing driver fatigue.

Every reference document goes obsolete if left to drift for eternity that is without review. Provide site assembled precast wastewater utility pumping station including specified controls pumps valves internal piping and precast concrete well and valve vault to be manufactured and furnished by Jensen Precast 855 468-5600. Rigid and exible pipelines couplings and other acces -.

Unlike the more commonly used standard box design which places a welding seam precisely at the edge of maximum stress the H-Box features horizontal plates that run perpendicular to the vertical plates below this critical area. Mack has led the industry in integrated design and manufacturing for over 100 years. The basic principle the types and selection Concrete pumps are tools used to convey liquid concrete from the source of concrete to the place of casting.

As s h o wn in Table 2 the quantity of coarse aggregate must be re d u c e d as the maximum size becomes s m a l l e r. The PUMPMAN Concrete Pump its various components like the heavy duty gate valve are completely made in India with 100 Indian Technology and are protected under multiple independent patent. In this category there are dwg files useful for the design.

THE TRUCK MOUNTED PUMP Concrete boom pumps are complex dynamic systems with a variable number of segments linked together by kinematic joints and moved by hydraulic actuators. Pumping processes and or into contractual requirements with third party contractors where pumping is out-sourced. 12Scope This guide for concrete pumping discusses equipment use proper mixtures for good pumpability and field prac.

This is tried-and-true performance you can count on. 11 Mix Design Concrete mix design is the process of selecting the proportions of cement water fine and coarse aggregates and if they are to be used additions and admixtures to produce an economical concrete mix. Over the long-term a concrete pump from Liebherr will prove.

Difficulties have been expe-rienced with pumping mixes that h a v e too large a pro p o r tion of coarse aggre g a t e. To view the largest previews click on the icon at the top. Numerous technical details simplify servicing.

Four-inch 4 slump is very common with normal weight concrete and is a good average slump for pumping. LEGENDARY MP ENGINES Power and speed controls are tuned for consistent speed and torque across the wide operating range required for smooth concrete pumping. In addition the Irish Standard IS.

Wide selection of files for all the needs of the designer. Locate with template Secured in pedestal or embedded into floor slab 1212017 PUMP INSTALLATION PRESENTATION 39. With an extended range of gears including available creeper gears it uses intelligent software and engine integration to automatically select the best gear and shift with speed and precision for an easier ride.

It is vital to everyone involved with concrete pumping from the concrete pump operator to the ready mix driver to the man on the end of the hose and to the construction contractor that at all times they all must make safety a top priority. EC4-1-2 gives general design methods for composite columns and in Annex G specific rules for concrete filled hollow sections. Consistency is the ability of freshly mixed concrete to flow.

The basic principle the types and selection of concrete pumps based on work are explained briefly in this article. Concrete like other engineering materials needs to be designed for properties like strength durability workability and cohesion. The Manual for practitioners in Nigeria using concrete must now replace the foreign manuals which has.

The PUMPMAN series concrete pumps are simple design easy to operate and easy to maintain concrete pumps which can develop high concrete pressures. INDUSTRY-LEADING DRIVELINE AND POWER DIVIDER. 3D Concrete Printing refers to the process used to synthesize a 3D model in successive layers of material to create an object eg.

The innovative pump units hydraulic system and state-of-the-art control ensures cost-effective operation of the concrete pump. Pumping is one of the major placement techniques used in the concrete industry to deliver concrete from the mixing truck to the formwork. Reserves the right to make changes to all specifications Not to be used through boom pipe NUMBER OF BOOMS 5 Sections FOLDING TYPE RZ Fold VERTICAL HEIGHT 392m 1287 HORIZONTAL REACH 352m 1118 UNFOLDING HEIGHT 82m 2610 1ST.

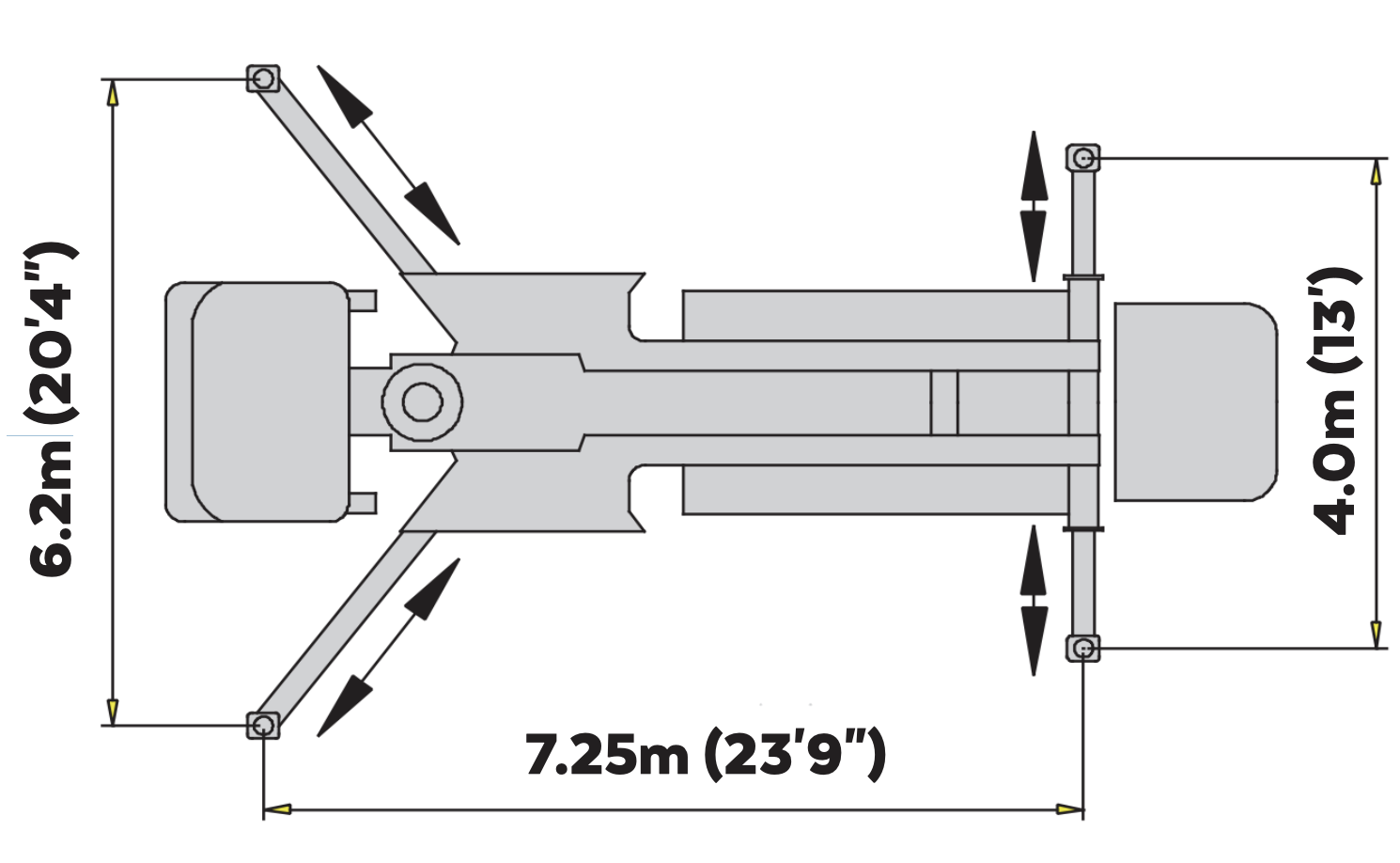

20 cell Pump Kit 18 cell Pump Kit GENERAL BOOM PUMP JXRZ 4O-516 Alliance Concrete Pumps Inc. Supervisors maintenance staff operators crew order takers and other staff involved in any aspect of concrete pumping shall receive adequate and appropriate training on the minimum standards contained within this handbook. The boom tip housing the device for placing the concrete may be very far from the pump or in very high place Figure 1.

Slump is a measure of concrete consistency or fluidity. Following a calibration exercise SCI and Corus concluded that a combination of the two methods was the best approach which is fully in. The detailed design of the concrete pump is subject to the Machinery Directive 200642EC and associated Irish legislation the European Communities Machinery Regulations 2008 SINo407 of 2008.

Concrete pumps concrete mixers construction machines. Putzmeisters exclusive H-Box design is best adapted to handle the day-to-day stresses of concrete pumping. In this way the end-activator ie.

Irjet Design Development And Testing Of Cfrc Tie Rod Https Www Irjet Net Archives V6 I8 Irje Structural Analysis Problem Statement Properties Of Materials

Fatigue Life Prediction For Boom Structure Of Concrete Pump Truck Sciencedirect

Irjet Structural Analysis And Design Of Pump House Structural Analysis Analysis Grade Of Concrete

Concrete Pump Truck Silhouette Boom Pump Stock Vector Illustration Of Natural Industry 195576137

My 3 Ponds Lesson Learnt From My First Pond Filter Design Koi Pond Design Pond Filters Pond Design

China Xcmg Official Manufacturer 39m Truck Mounted Concrete Pump Photos Concrete Diy Construction Vehicles Trucks

0 comments

Post a Comment